It is completely reversed process of traditional manufacturing process. As in subtractive manufacturing process the object is manufactured by removing the material by performing operations like milling, drilling, boring etc. in traditional CNC Machine, whereas in 3d printer an object is manufactured by adding material to manufacture the object.

To 3d print an object it is need to be designed in a CAD or 3d modelling software first and then saving the design in the digital formats like stl, 3mf etc. then a slicer software is used to process the file in hundreds or thousands of thin layers of cross section of the object and then the file is transferred to the 3d printer for the printing or manufacturing of the object where it is manufactured as printing layer by layer of sliced cross section of the object.

3d printing or additive manufacturing is the latest manufacturing technology which is rapidly becoming a trend for producing goods and objects worldwide...as the part can be produced in comparatively less time and money. It is being used in all sectors of manufacturing from the furniture to automotive and aviation sectors. Even organizations like NASA, SpaceX and ISRO use 3d printing.

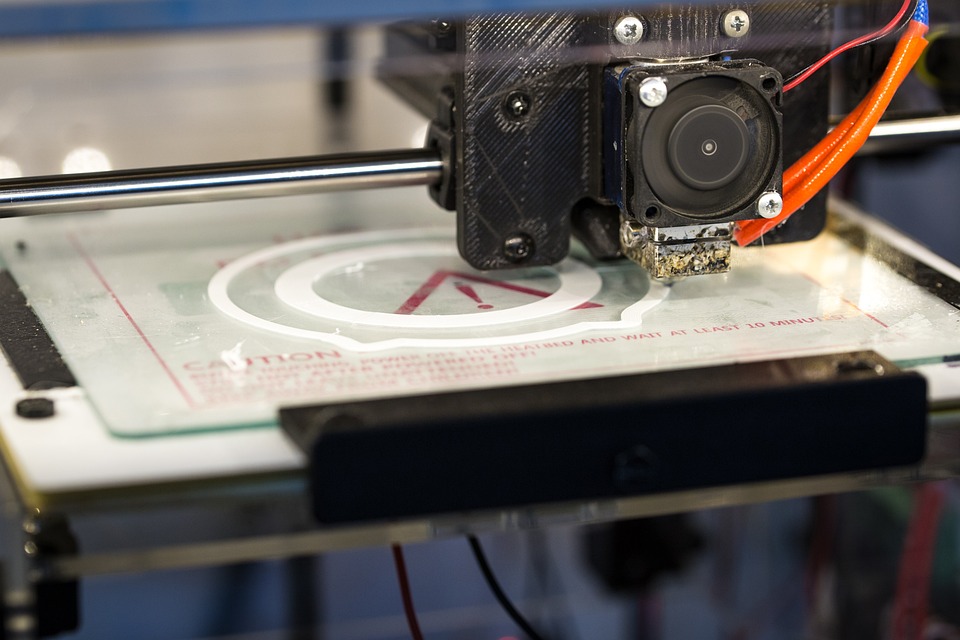

Now let's understand the FDM technology

In FDM process thermoplastics like ABS, PLA etc. is melted and then extruded in thin filaments with the help of heated nozzle as thermoplastics possess ductility. This extruded filament is then applied layer over layer to form the object's cross-section. As the object is previously sliced in the slicer software, it starts forming the cross section and adding layers over it to form or manufacture the complete object in three dimension. FDM 3d printers are the most commonly used 3d printers for the low cost and cheap rapid prototyping or production of cheap goods.

When printing for a certain project, most companies or businesses settle for wholesale cheap printing to lower printing costs. However, though bulk printing is the most cost-effective way to print your advertising materials, it would be best to know the pros and cons to decide if it really suits your need. You have to be careful in choosing what printing process to use to avoid a shoddy print job. asia printing pte ltd

ReplyDeleteTherefore, direct warm printing is frequently utilized for reestablish circles, reinforcement programming duplicates, month to month telephone and finance logs,

ReplyDeletebank proclamations and at whatever point one-time utilization of a plate is the standard.

https://dry-transfer-letters.business.site/

Legal contracts sent via fax maintain their formatting and structure.

ReplyDeleteThe Fax Services Authority